Manufacturers embrace AI: Study reveals familiarity and investment in automation

In this article, we explore key insights from the CohnReznick Manufacturing Checkup study. Discover critical findings on AI adoption, investment trends, and key challenges in the manufacturing sector, and how leveraging AI to drive growth, improve performance, and stay competitive.

Progress toward AI-based automation continues; And as it does, the opportunities to leverage emerging agentic AI and other AI automation capabilities becomes clearer. Incorporating AI skills and experience in manufacturing companies will only help increase the opportunity to leverage AI.

In a recent study, a large, diverse group of executives at medium- and large-size manufacturers (by design) participated in the CohnReznick Manufacturing Checkup, representing many types of firms.

The vast majority of participants (92%) were “very familiar” with their company’s use of artificial intelligence while only 8% were “somewhat familiar.”

This shows that opportunities exist to examine data by major groupings, such as by revenue, industry, and respondent function (e.g., senior leadership). Furthermore, participants’ awareness of their companies’ use of artificial intelligence lends credibility to the study findings, which we explore more in depth below.

What is driving your company's willingness to consider using AI?

AI Readiness Findings

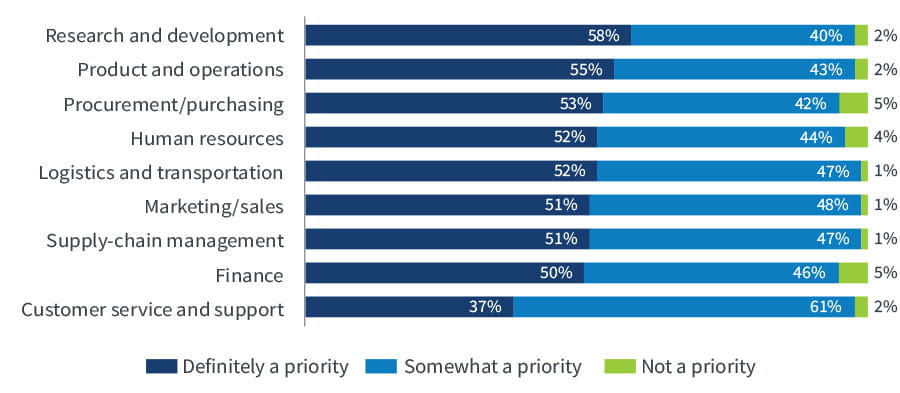

Three-fourths of manufacturers are currently investing in and applying AI, and most functions are AI priorities for a majority of firms with most manufacturers using it to grow sales, improve performance, and increase productivity.

However, the application of AI is not without concerns for manufacturers. The study found that the top concern is cybersecurity and privacy (60% of manufacturers), followed by cost (46%) and employee concerns about AI (42%). These concerns are driving most manufacturers to have AI policies in place or in development.

Formal adoption of AI is occurring across manufacturing, and those companies on the sidelines will find themselves at a competitive disadvantage. Even small pilot projects serve to enhance AI understanding and readiness.

Like any new technology, there are concerns about AI’s unintended consequences. Manufacturers can establish policies and practices to minimize these worries and initial opportunity scans can highlight both opportunities for automation as well as needed controls over impacts.

AI Usage Findings

Most manufacturers are making investments in AI for different functions, with many making significant investments.

Manufacturers are using or considering AI for a wide range of activities. The use of AI to analyze data is a common objective for many functions, according to our study: e.g., analyze transportation performance for logistics (57% of manufacturers), analyze fraud report for finance (53%), and analyze production performance for production and warehouses (52%).

For which of the following functions is implementing AI a priority?

(Select all that apply)

As manufacturers invest in AI, they should develop detailed plans for what they hope to accomplish and the returns on investment they expect.

Many activities within manufacturing organizations offer proven opportunities to leverage AI beginning with analysis of existing data and then moving on to more complex applications that automate processes.

AI Outcomes

About half of manufacturers in the study have some practices in place to help them deliver successful AI outcomes – but few report workforce training and skills analysis to support AI usage.

Most manufacturers report a medium or high impact of AI on their businesses and most report using outside support/contractors for AI activities; 57% report “complete outside support” for AI policy/governance.

All AI best practices included in the study should have greater usage and manufacturers should identify and resolve AI support gaps.

CohnReznick has worked with a range of manufacturers to develop and implement AI governance structures for a strategic AI foundation, as well as helping them deploy processes such as data quality, technology assessment, planning, and execution to achieve AI objectives.

Over the next three years, what percentage of technology investments will be for AI?

To what extent has AI impacted your company's business performance?

Conclusion

We are still in the earliest stages of AI development, experimentation, and adoption. Manufacturers have a history of considering technology investments against the backdrop of costs and change impacts.

The CohnReznick Manufacturing Checkup — Artificial Intelligence was designed to help executives of medium- and large-size manufacturers improve their use of — and impact from — artificial intelligence.

The research study was conducted by The MPI Group, an independent research firm, and was fielded in October 2024.

CohnReznick and MPI conducted this study to provide timely insights into the opportunities and risks of moving forward with AI, or waiting. Some progressive AI experience is increasingly important to remain competitive. For a deep dive on the survey results, register for this webinar(Opens a new window).

Contact

Let’s start a conversation about your company’s strategic goals and vision for the future.

Please fill all required fields*

Please verify your information and check to see if all require fields have been filled in.

Related services

Our solutions are tailored to each client’s strategic business drivers, technologies, corporate structure, and culture.

This has been prepared for information purposes and general guidance only and does not constitute legal or professional advice. You should not act upon the information contained in this publication without obtaining specific professional advice. No representation or warranty (express or implied) is made as to the accuracy or completeness of the information contained in this publication, and CohnReznick, its partners, employees and agents accept no liability, and disclaim all responsibility, for the consequences of you or anyone else acting, or refraining to act, in reliance on the information contained in this publication or for any decision based on it.

.jpg?h=400&w=1380&hash=7250D78B399085314B0A2C3E05EA62E6)